Anodising

Anodising is SeaMac's recommended finishing method for our product.

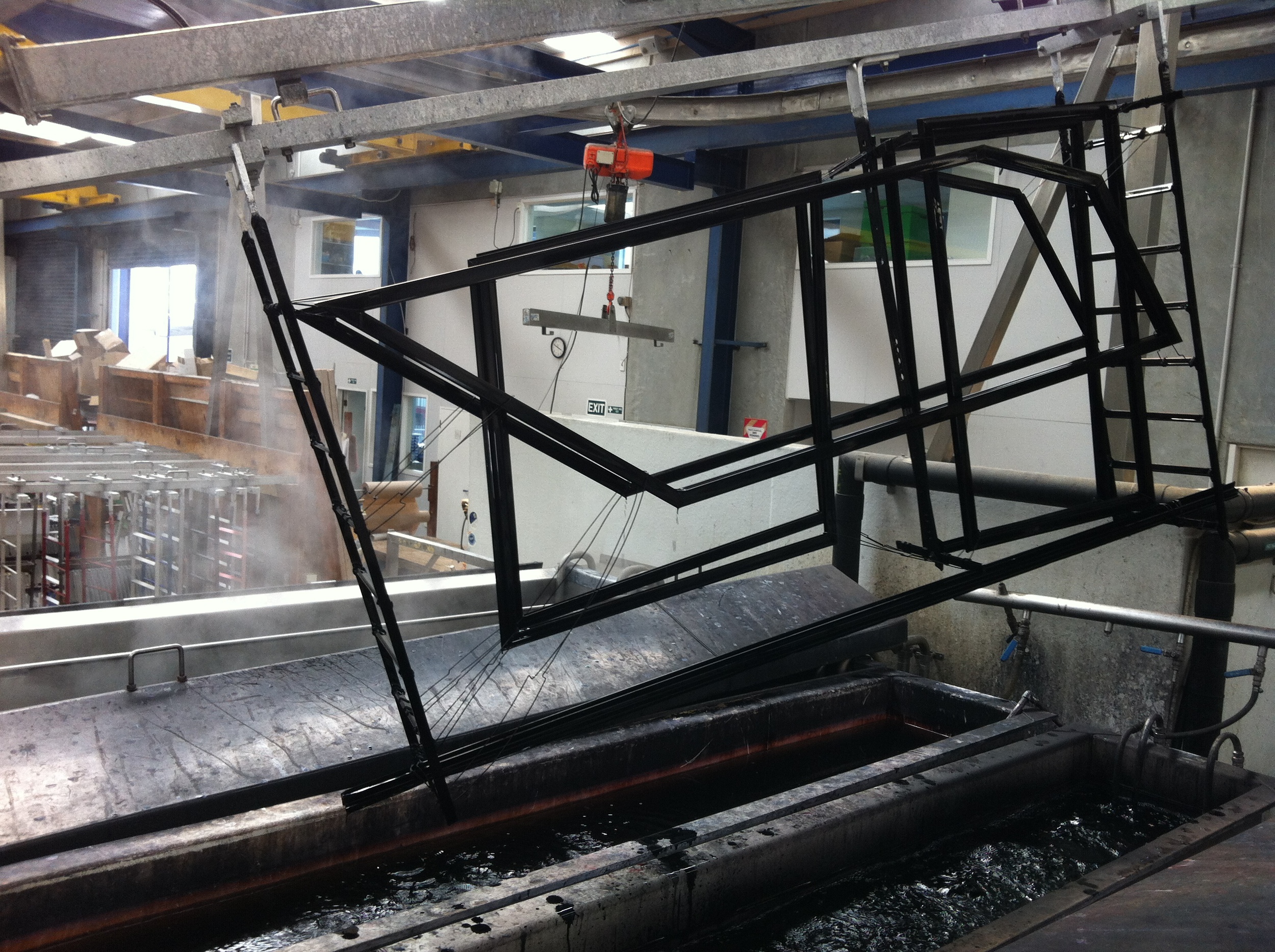

Anodising is IN the metal, not ON the metal, which differentiates it from powder coated or painted surface finishes. This is achieved via an electrochemical bathing process (see pictures below), so it will withstand the harsh marine environment.

As you can see in the photos below, the frames are all hung and dipped into a series of baths where different processes cleanse, impregnate and seal the surface of the metal, giving you a hard coat finish.

The most popular, and tried and tested, finish is silver but we can also offer black, which is very popular.

Powder Coating

In some situations a white or coloured product is required. In this instance, although its not our recommended surface finish, we can supply powder coated joinery. In our experience this is best limited to aft-facing product, i.e aft access doors and cockpit area windows. The joinery in your boat is constantly blasted by the sea, salt and wind driven sand, but in the cockpit area they are offered some protection and powder coating has proven to be acceptable. Please understand that we do not apply this finish thus its quality and ability to withstand the harsh marine environment is out of our control.

Powder coating is a paint finish, and a very good finish at that, however with no maintenance (cleaning, cutting and polishing) it will deteriorate as your motor vehicle would if left in a marine environment.

For further information on this finish please contact us.